Storage & Distribution System

Optimally Designed Storage & Distribution System That Operates Reliably and Efficiently 24 x 7

Storage & Distribution System

Optimally Designed Storage & Distribution System That Operates Reliably and Efficiently 24 x 7

Product Description

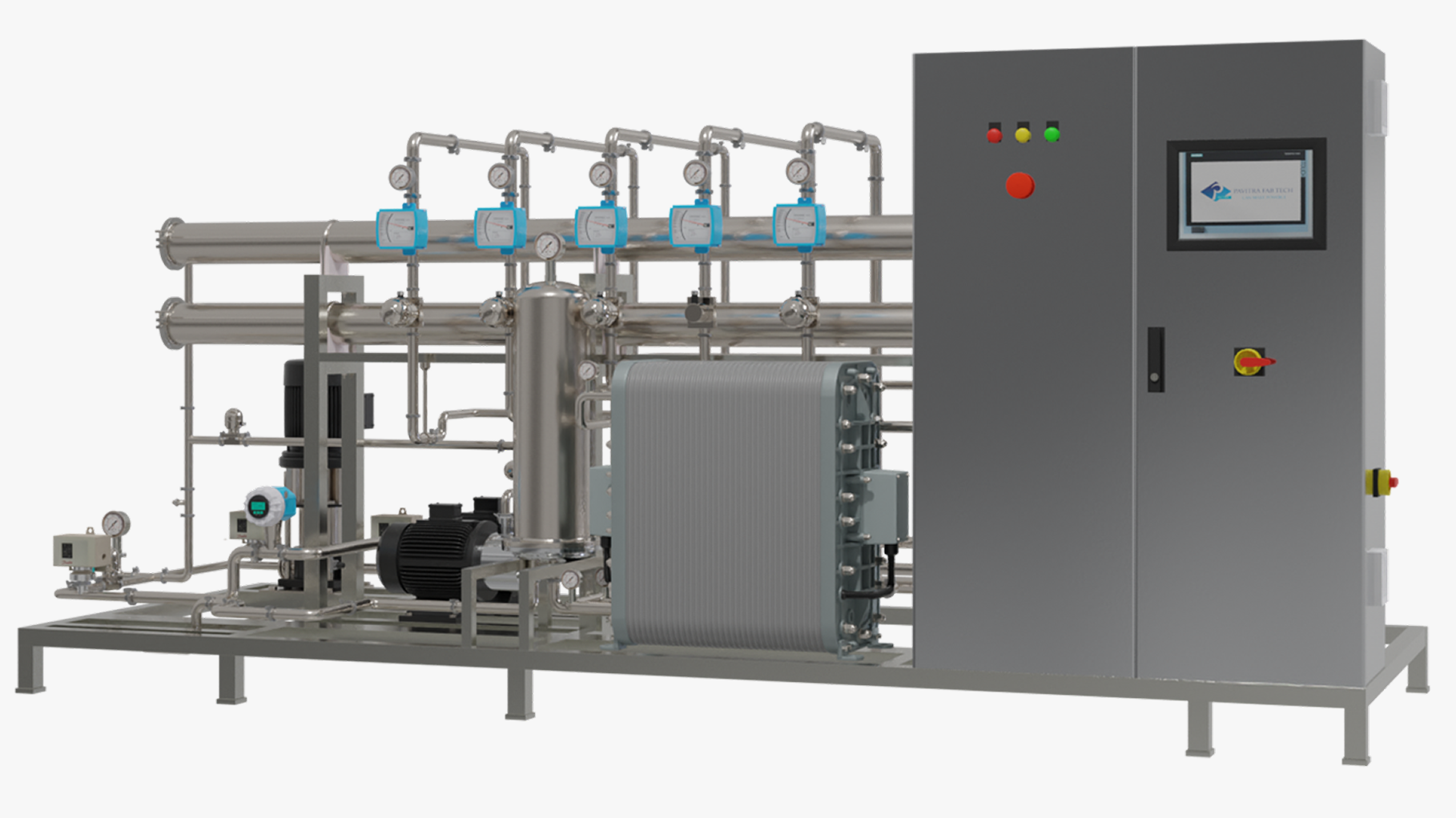

A highly efficient and reliable system designed for 24/7 operation, ensuring optimal storage and distribution of Purified water uses in pharmaceutical industries.

A specialized system designed fully automation to store and distribute Purified water while maintaining quality from generation to point of use with entire loop dead leg free (1:100). Loop should be SS316L with electropolished (Ra ≤ 0.5µm) surfaces for corrosion resistance. Ensures water meets compendia standards (USP, EP, JP, WHO).

3600 View

Click and drag to rotate the system. Click hotspots to know more

Key Features

Material of Construction

Features:

- SS316L stainless steel (electropolished, Ra ≤ 0.4µm) – optimal hygiene & durability.

- Orbital welding – smooth, crevice-free joints for contamination prevention.

- Tri-clamp fittings – easy disassembly for maintenance & validation.

- Passivated surfaces – enhances corrosion resistance.

- FDA/CE-compliant materials – all wetted parts meet regulatory standards.

Storage Tank Design

Features:

- Hydrophobic 0.2µm vent filter – prevents microbial ingress.

- 316L spray ball system – ensures full CIP coverage.

- Sloped bottom (≥1° incline) – eliminates water stagnation.

- Insulated/jacketed design –maintains temperature control.

- Level, pressure & temp sensors – real-time monitoring & alarms.

Distribution Loop Design

Features:

- Continuous turbulent flow (>1.2 m/s) – prevents biofilm formation.

- Zero-dead-leg valves (diaphragm type) – hygienic, fully drainable.

- Dead legs <6D – ensures full drain ability (no stagnant zones).

- High-purity centrifugal pumps – low-shear, low-particulate operation.

- Sanitary instrumentation – all sensors & gauges meet 3-A standards.

Water Quality Assurance

Features:

- Meets USP/EP/JP/WHO PW specs – full compliance guaranteed.

- Online monitoring (TOC, conductivity, flow, temp) – real-time purity control.

- Sampling valves – accessible points for QC testing.

- Alarm system – immediate alerts for out-of-spec conditions.

- Periodic sanitization –automated thermal/chemical cycles.

Sanitization & Biofilm Control

Features:

- Hot water sanitization (80°C+) – proven microbial reduction.

- Ozone/chemical sanitization –optional disinfection methods.

- Automated CIP/SIP cycles – reduces manual intervention.

- Validated sanitization protocols –ensures efficacy & compliance.

- Rouging-resistant surfaces –minimizes corrosion & biofilm risk.

Automation & Compliance

Features:

- PLC/SCADA control – full system automation with HMI.

- 21 CFR Part 11 compliance – secure data logging & audit trails.

- Remote access & alerts – real-time monitoring from any location.

- User access tiers – role-based permissions for operators/QA.

- GMP/ISO documentation –ready for validation (FAT/IQ/OQ/PQ).

Key Features :

Design & Engineering

Efficient system design, with minimal pressure drops, right pump selection, VFD for power efficiency and high quality materials and surface finish to ensure bacteriostatic condition.

High Reliability

System designed for consistent performance, high reliability and low maintenance.

Instrumentation & Control

Precision & high quality instruments that are reliable, Monitoring of critical parameters with data logging with GAMP 5 and 21 CFR Part 11 compliance

In build features

System designed for in-situ hot water sanitization with precise steam control.

Storage Tank Jacketed, SS316L

The storage tank is designed for optimal tank turnover, with high internal surface finish. It is jacketed and insulated for high thermal efficiency. A 360o spray ball ensures uniform wetting of the tank.

- Jacketed and insulated SS 316L storage tank

- Electropolished for high internal surface finish

- Option of design as per ASME, ASME-BPE

- 3600 spray ball for uniform rinsing

- Precise Steam control for hot water sanitization

Spray Ball (360º)

Compact, Self-draining, Spray ball designed for 3600 coverage is designed for flush cleaning of the storage tanks. They are designed for powerful flush cleaning at low pressure.

- 3600 Spraying

- Compact, Self draining type

- No moving parts

- Stainless Steel, 316L

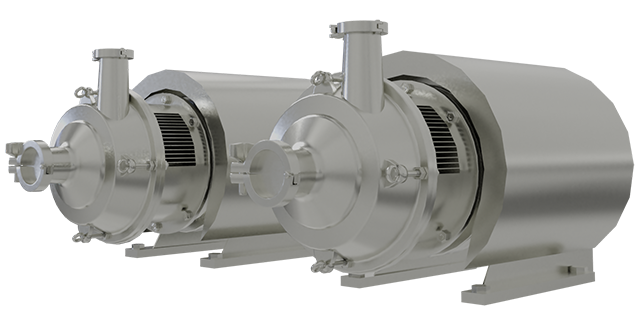

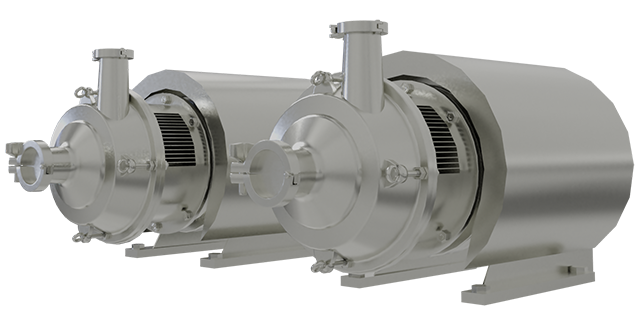

Twin Sanitary Centrifugal Pumps

Our twin (1 working, 1 Standby) sanitary, SS316L pumps are designed for high efficiency, lower operational cost. They are also designed to optimize bacterial control, prevent rouging, reduce energy consumption, minimize maintenance and sanitation.

- Sanitary, SS 316L, Construction

- Easy swing change over in case of pump failure

- Pump driven by power saving VFD for higher efficiency

- Reliabel, robust pump design with minimal downtime

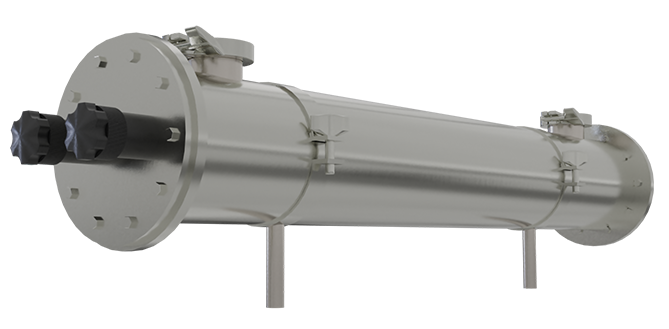

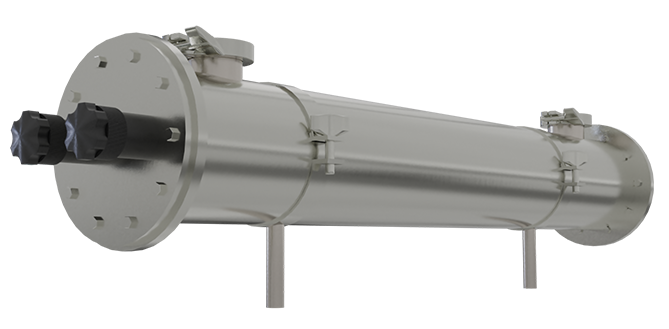

Sanitary UV System

Our UV systems are designed for to meet the stringent standards of the pharmaceutical and bio-pharmaceutical industry. Along with the UV lamps, the system also contains dosage monitoring, intensity and the lamp life as well. The system features all sanitary design construction with all contact parts in SS316L with electropolished inner finish.

- Integrated with Intensity monitor

- Strong disinfecting frequency of 254nm wavelength

- Monitor UV dosage and lamp life

- High performance, low maintenance

PLC Control Panel

We offer Integrated PLC based control panels with intuitive touch screen HMI. With option to connect with DCS / SCADA, our panels are designed to comply with CFR 21, Part 11 and GAMP-5.

- Integrated and compact

- Touch screen HMI, SCADA / DCS option

- Intuitive software with MIMIC Panel

- Built in safety features

- CFR 21, Part 11 and GAMP 5 compliance

- Reduced downtime

Distribution Disinfection & Monitoring

Our very compact Distribution, Disinfection and monitoring skid is designed to be compact, easy of access and contains all critical monitoring instruments and controls for monitoring of flow, pressure, temperature, conductivity, TOC, UV intensity etc. It is also pre-wired and pretested for plug and play.

- Compact, skid mounted, SS316L construction

- Pre-wired and pretested, Plug & Play

- Integrates Dual pump and UV system

- Instruments to measure flow, pressure, temperature, conductivity etc.

- Built-in auto dumping feature for high conductivity

Potable Water Storage & Distribution System

A system designed to store and distribute water that is safe for human consumption (meeting regulatory standards like WHO/EPA) but not necessarily sterile.

- Material: Uses corrosion-resistant materials like SS 316L or food-grade polyethylene with antimicrobial linings.

- Electropolished for high internal surface finish

- Option of design as per ASME, ASME-BPE

- 3600 spray ball for uniform rinsing

- Precise Steam control for hot water sanitization

Purified Water Storage and Distribution System

Compact, Self-draining, Spray ball designed for 3600 coverage is designed for flush cleaning of the storage tanks. They are designed for powerful flush cleaning at low pressure.

- 3600 Spraying

- Compact, Self draining type

- No moving parts

- Stainless Steel, 316L

WFI Storage and Distribution System

Our twin (1 working, 1 Standby) sanitary, SS316L pumps are designed for high efficiency, lower operational cost. They are also designed to optimize bacterial control, prevent rouging, reduce energy consumption, minimize maintenance and sanitation.

- Sanitary, SS 316L, Construction

- Easy swing change over in case of pump failure

- Pump driven by power saving VFD for higher efficiency

- Reliabel, robust pump design with minimal downtime

Pure Steam Distribution Piping

Our UV systems are designed for to meet the stringent standards of the pharmaceutical and bio-pharmaceutical industry. Along with the UV lamps, the system also contains dosage monitoring, intensity and the lamp life as well. The system features all sanitary design construction with all contact parts in SS316L with electropolished inner finish.

- Integrated with Intensity monitor

- Strong disinfecting frequency of 254nm wavelength

- Monitor UV dosage and lamp life

- High performance, low maintenance

Different Types

- Potable Water Storage & Distribution System

- Purified Water Storage and Distribution System

- WFI Storage and Distribution System

- Pure Steam Distribution Piping

Why This System?

- Regulatory Ready – Designed to meet FDA, EU GMP, WHO.

- Zero Contamination Risk – Dead-leg-free, biofilm-resistant design.

- Energy Efficient – Optimized pumps & heat recovery options.

- Low Maintenance – Sanitary design reduces downtime.

- Future-Proof – Modular, scalable for expansion.

Our Portfolio

Schedule a Meeting

Need a customized water solution for your industry? Contact us today for expert design and implementation!

Schedule a Meeting

Need a customized water solution for your industry? Contact us today for expert design and implementation!